WM Series Motors

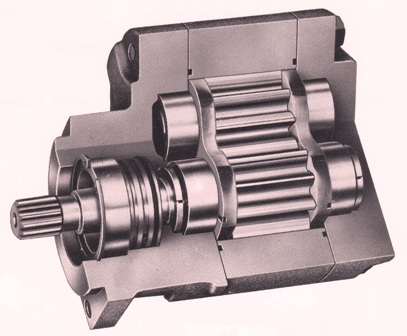

July 24, 2020 Comments Off on WM Series MotorsWM Series Motors These types of motors work best with winches and other operations that have to have alot of torque to do the job. WM motors are assisted by a computer program that helps with displacement, tooth strength and power operations. On a WM76 the displacement is 4.1 cir per inch of gear width…

Read more