John Deere Crawler 755B Install/Remove Connector Disk

John Deere Crawler 755B Install/Remove Connector Disk

July 10, 2018 Comments Off on John Deere Crawler 755B Install/Remove Connector DiskAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

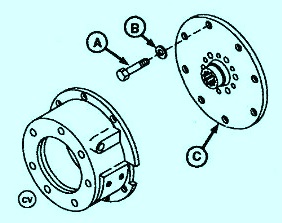

Remove and Install Element Connector Disk

Remove engine.

Take off cap screws and washers to remove disk.

Make repairs as necessary.

Clean thread of cap screws, tapped holes in flywheel and mating surface of disk and flywheel.

Apply medium strength to thread lock and sealer to threads of cap screws, tapped holes and mating surface of disk and flywheel.

Install disk with longer side of hub towards flywheel.

Install washers and cap screws. Tighten cap screws to 35 lb-ft.

Apply lubricant to internal splines of hub.

Put plastic gasket to mating surface of clutch and flywheel housing. Install engine.

Apply thread lock and sealer (med. strength) to threads of clutch housing to flywheel housing cap screws. Tighten cap screws to 45 lb-ft

You need help with this topic or any other ones, to your John Deere problems, let us know.

Comment here on this blog or call us at 800-361-0068

email: sales@hydrostatic-transmision.com