Sundstrand Sauer Danfoss Series 20 – Axial Piston Slipper Pad Design

Sundstrand Sauer Danfoss Series 20 – Axial Piston Slipper Pad Design

July 6, 2016 Comments Off on Sundstrand Sauer Danfoss Series 20 – Axial Piston Slipper Pad DesignAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

Sundstrand Sauer Danfoss Series 20 – Axial Piston Slipper Pad Design

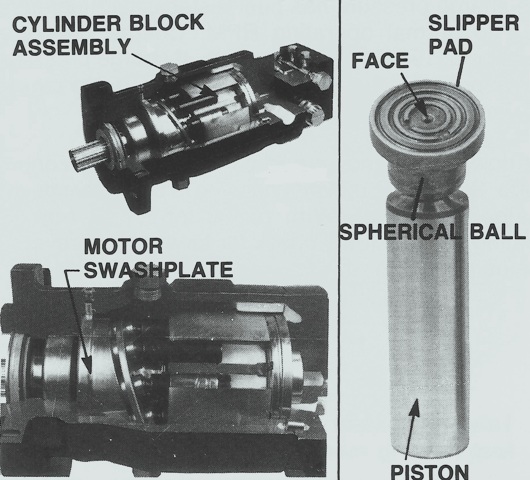

They have 9 pistons that go into the cylinder block. When the cylinder block rotates, the pistons are pushed in and out of the bores by the angle of the swashplate. The results of it is a specific amount of fluid that is displaced for every time the revolution of the cylinder block. In a pump, the fluid is pushed out as the angle of the swashplate forces the pistons into the bores. In a motor, system pressure that builds up against the piston makes it to slide down the inclined face of the swashplate resulting in output rotation.

The slipper pad clinches to a spherical ball on the end of the piston making a ball and socket joint. This lets the slipper pad to tilt at any angle and engages with the swashplate. The face of the slipper pad slides on a hydrostatic fluid that uses fluid pressure to align internal forces.

If you need further assistance with this, please let us know.

Call 800-361-0068

email: sales@hydrostatic-transmission.com