Hydraulic Shaft Stresses Part 2

Hydraulic Shaft Stresses Part 2

March 3, 2016 Comments Off on Hydraulic Shaft Stresses Part 2At our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss;

Hydraulic Shaft Stresses Part 2

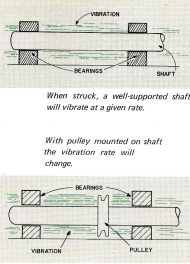

Another type of stress on a shaft is Vibration, which will have a definite behavior on the shaft. Also, speed on the shaft along with vibration will affect how the shaft works.

If the shaft is rotated at an overwhelming speed, a point will come to where the entire setup will vibrate violently. The reason for this is the shaft is defecting uncontrollably.

The speed of the shaft rotation which is same to the shaft’s occurrence of vibration is known as Critical Speed.

To deter from damaging the shaft at such a speed, the engineer will design a shaft with specifics in mind that will have it run below speed to avoid breakage of the shaft.

Such critical speeds and vibration have a direct effect on the bearings as well.

Bearing failure will see excessive wear when vibration has accured. Where the shaft lies will have affect on its movement since it is controlled and confined by a bearing, which will fail if too much vibration is present.

And thus you will hear the sounds that is something wrong.

send us your comments or questions, be glad to help you out.

call us at 800-361-0068

email: sales@hydrostatic-transmission.com