Sundstrand Sauer Danfoss – How to Select the Right Unit Size

Sundstrand Sauer Danfoss – How to Select the Right Unit Size

February 17, 2016 Comments Off on Sundstrand Sauer Danfoss – How to Select the Right Unit SizeAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

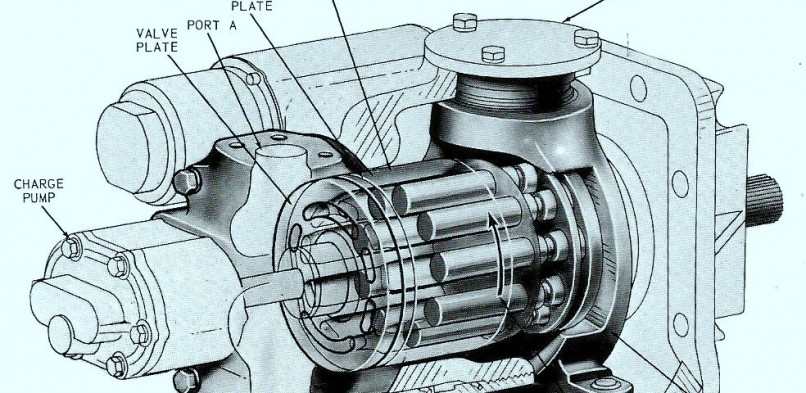

Sundstrand Sauer Danfoss Series 20

How to Select the Right Pump and Motor Size

The Series 20 has 8 different sizes, ranging from 2.0 cu in to 20 cu. in. They are offered in different combinations to give the best performance. To best do this, you must have knowledge of pump input conditions and motor requirements.

Here are the following parameters:

1. Power source, horsepower rating, high idle (unloaded) speed and torque characteristics.

2. Horsepower available to pump at rated RPM after deducting parasitic losses.

3. Motor Output Torque

A. Maximum Required

B. Normal Operating Level

4. Motor Output Speed

A. maximum Required

B. Normal Operating Level

5. Transmission Life Requirements

To know the output conditions, information must be available on gear ration and efficiency, wheel load radius, rolling resistance, etc.

To select the right transmission the motor size is first determined.

1. Calculate the required maximum motor torque and speed using the right gear ratios, etc.

2. Make the required motor size using the motor performance curves. Also determine maximum motor flow from the curve.

3. Make the pump size from the pump performance, curves to provide the maximum flow required by the motor.

If the pump is to be direct driven, the pump speed may not be enough to drive the motor. Here are some procedures to correct it:

1. Change the final drive ratio to match the motor speed requirements to that available at the pump.

2. Increase the speed of the power plant.

3. Select a larger pump.

A quicker way of figuring out minimum transmission size is the corner horsepower method.

1. Calculate the required CHP of the system output DBP x mph/375

2. Select a motor with a CHP equal or greater than the system requirement, including final drive efficiency.

3. Select the final drive ratio to match motor output (speed or torque) to system requirement (MPH or Rim Pull).

4. Select a pump of equal size to the motor.

5. Select input ration to drive the pump at a speed approximately 5% faster than the maximym required motor speed (refer to charts for pump and motors speeds limits).

6. Check maximum output speed and load using efficiency from performance charts. Adjust gear ratio selections, if necessary.

Please leave comments, questions or your experiences with this topic.

hydrostaticpumprepair.com