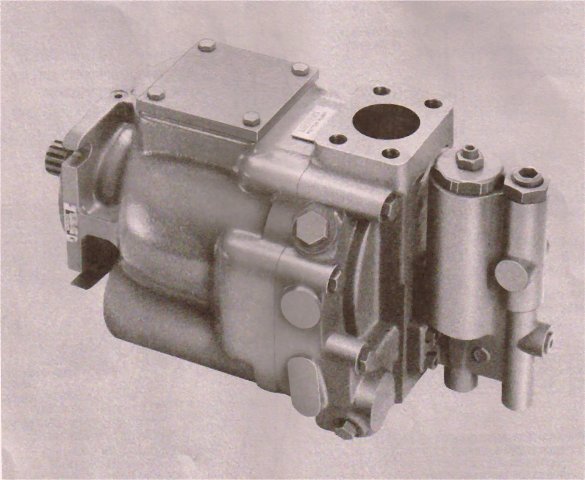

Vickers 45PGM Fixed Inline Hydraulic Piston Pump Repair

Vickers 45PGM Fixed Inline Hydraulic Piston Pump Repair

June 2, 2016 Comments Off on Vickers 45PGM Fixed Inline Hydraulic Piston Pump RepairAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic

Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

Vickers 45PGM Fixed Inline Piston Pump Repair

Put the whole unit with tubing into

an arbor press with drive spline up. See Figure 20.

Push the drive shaft through the bearing

and out of the unit. A 0. 001 inch press exists linking

the shaft and bearing so substantial force is necessary

to remove the bearing from the shaft.

Remove yoke as follows:

Remove yoke bearing parts (49 through

58). Be wary not to damage the seal on the long

pintle during removal If burrs are present on the pintle,

clean-up with an India stone before removing pintle

cover.

Keep shims (51) and (56) if possible and

use a micrometer to determine each shims thickness.

If the yoke pintle bearings are not faulty, the same

shims or new shims of the same thickness will be

needed to pre-load the bearings at the time of set up.

If shims (51) or (56) were damaged during disassembly, a yoke bearing pre-load modification will be vital at assembly.

Slide yoke (61) from side to side to release

yoke bearing races (59) or (60) within the housing. The

races are a normal slip fit but may be tight. Use an

open end wrench connecting the yoke and the pintle bearing

to help slide out the races. Use the amount of relevant pressure to

bearing (59) or (60) at the approximate center and al¬

low the bearing rollers to gently push the race out of

the housing.

Remove yoke (61) from housing (32).

Raise front shaft bearing (62) from the housing.

DO NOT remove the bearing race unless bearing was

found faulty. Refer to Figure 21 for bearing race

removal instructions.

Remove retaining ring (63) and push shaft

seal (64) out of the housing. Utilize a short piece of 1 ^”

heavy wall tubing as a tool or if the yoke was not re¬

moved, apply a tar ass rod and work from the inside of the

housing to drive shaft seal (64) from the housing.

REMINDER

Every one of the parts ought to be thoroughly cleaned and kept clean during examination and assembly. Clean every one of the detached parts, using a commercial cleaner that is similar in temperament with the system fluid. Compressed air may be used in cleaning, but it is the filtering that will remove the water and contaminates. Clean compressed air is predominantly useful in cleaning valve block passages.

INSPECTION REPAIR AND REPLACEMENT

MAKE NOTE OF

Restore all parts that do not meet the following requirement:

Examine vane pump shaft (17) for wear and chip¬-

ped splines.

Make sure bearing spacer (37) for burrs. Eliminate

small burrs with an India stone.

Scrutinize cylinder block face (38) for wear,

scratches and/or erosion involving the cylinders. Check

the spring, washers and retaining ring removed from

inside the cylinder block.

Ensure each cylinder block bore for unnecessary

wear. Use the piston and shoe sub-assemblies (39) for

this reason. The piston should be a close fit and

glide easily in and out of the bore. No bind can be tolerated.

If binding is obvious, clean the cylinder block

and piston, oil with clean hydraulic fluid and try

once more Even minor contamination of the fluid could

be the reason the piston will freeze up in the cylinder bore.

Examine both piston and shoe sub-assembly (39)

for a maximum end play of 0. 003 inch between the

piston and shoe.

Each shoe of the nine piston and shoe S/A’s

(39) must be ensured of thickness.It should be

within 0. 001 inch of each other. If out of tolerance,

restore the whole set of piston and shoe sub-assemblies simultaneously.

Check shoe plate (40) for too much wear and

cracking in the area of spherical washer (41). If serious

wear or cracks are found, change the shoe plate and

spherical washer at the same time.

Make sure spherical washer (41) for burrs, wear

and likely scratches due to pin (42) breakage. Re-

place if wear is unnecessary.

Look over pins (42) for equal length, too much

wear and probable bending. Replace all pins simultaneously

if one is not working.

The pin retainer (43) might develop burrs; move all burrs with an India stone.

Examine the bronze face of wafer plate (35) for

to much wear, scratches, and likely fracture. If

the wafer plate is cracked, make sure the new plate

rests flat next to the valve block at assembly and that

wafer plate pin (36) does not level too far and hold the

wafer plate away from the valve block.

Inspect shaft (48) for broken splines, burrs,

and wear in the area of shaft seal (64). Remove burrs

with an India stone. Wear in excess of 0. 005 T. I. R.

has to have shaft replacement to stop leakage.

45 gpm fixed inline piston pump

(M) pfb45-(F)rf-10/11

(M) pfb45 (F) LF 10/11

F6 PFB45(F) 10/11

I-3250 s

Call us 800-361-0068

email us at sales@hydrostatic-transmission.com

or we will be glad to answer any questions you may leave in the comments.