John Deere Crawler 755B – Service for Metric Four Bolt Flange Fittings

John Deere Crawler 755B – Service for Metric Four Bolt Flange Fittings

April 27, 2016 Comments Off on John Deere Crawler 755B – Service for Metric Four Bolt Flange FittingsAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

John Deere Crawler 755B

Service Instructions for Metric Series Four Bolt Flange Fittings

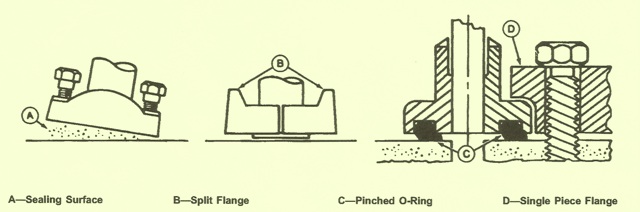

You will need to clean all sealing surfaces (A). Look for any scratches or causes for leaks. Any coarseness will result in seal wear and extrusion, as well as out of flat will produce the same results. If you can’t polish out the problem, then it will need to be replaced.

Put in the right o ring (and backup washer if it needs it) into groove using petroleum jelly to make it stay in place.

Split Flange: Lightly put together the split flange halves (B). Making sure the the split is vertically and horizontally correct with each other. Hand tighten cap screws to keep the parts in place. Try not to pinch the O Ring (C).

Single piece flange (D): Put the hydraulic line in center of flange and put the four cap screws in. The flange needs to be centered on port. Hand tighten cap screws to keep the flange in place. The o ring ..try not to pinch it.

After all the components have been put in place and the screws have been tightened by hand, start tightening the screws one at a time. Tightening one then the one diagonally from the other, til they are all tightened. You may need to look at the chart below to help guide you on the torque you need to put on the screws.

Do not use an air wrench or over tighten the screws.

Torque Chart

Thread N-m lb-ft

M6 12 9

M8 30 22

M10 57 42

M12 95 70

M14 157 116

M16 217 160

M18 334 246

M20 421 318

These are the recommended torques working pressure. Going beyond these torque values will result in the flange and cap screws bending and connection breakdowns.

If you need any questions answered on this topic, please let us know.

You can call us at 800-361-0068

Email: sales@hydrostatic-transmission.com