Automatic Grease Lubricating Systems

Automatic Grease Lubricating Systems

March 28, 2016 Comments Off on Automatic Grease Lubricating SystemsAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss;

Automatic Grease Lubricating Systems

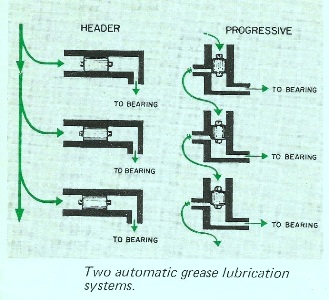

Automatic grease lubricant systems are generally used in industrial settings. The greasing applications have two main types: Header and Progressive. The header system provides grease all they time to a main line to separate metering valves, which supply the bearings. The progressive system the grease first goes to the metering valve, which in turn takes apart of the grease and supplies it to the bearing. The rest of the grease is divided up to next point, the metering valve takes its portion of grease and divides it up to its bearings and so forth.

The header system is split into a single line system and two line system. They both have similar operations. Single line system the grease is supplying the metering valve by a single line. When all the grease has gotten to the metering valves, the flow stops and the supply line is allowed to vent. You need to let it vent itself, it depressurizes the line and the valves function by letting the pressure of the lubricant inside them.

In a two line system, grease passed to the metering valves thru tow lines instead of one.As grease is passed to one side of the valve, grease on the other side is dispersed to the lubricating points. The grease flow is then sent the other way thru a control and the line that was under pressure is now vented. That allows the grease pressure on the second line to push the metering valve in the opposite direction, causing lubricant to be allotted to another lubrication point.

Progressive metering is centralized lubrication system. This kind of system seems like it hard to work on, because of the many lines it has. If you have a diagram, it is quite easy to follow the lubricant thru the system. When the system is working properly, the grease first goes to the lowest section of the valve housing. Then as the grease goes thru the section, it goes onto the second section just above the first. This makes the piston to shift to the right. As it shifts, lubricant from the right side is dispersed to the point to be lubricated. Also, the metering valve is situated so the incoming lubricant is flowing to the third section of the housing positioned just above the second. The same action happens to the piston in the third section that happens to the piston in the second.

We are here if you need a question answered, leave us comment.

or call us at 800-361-0068

hydrostaticpumprepair.com